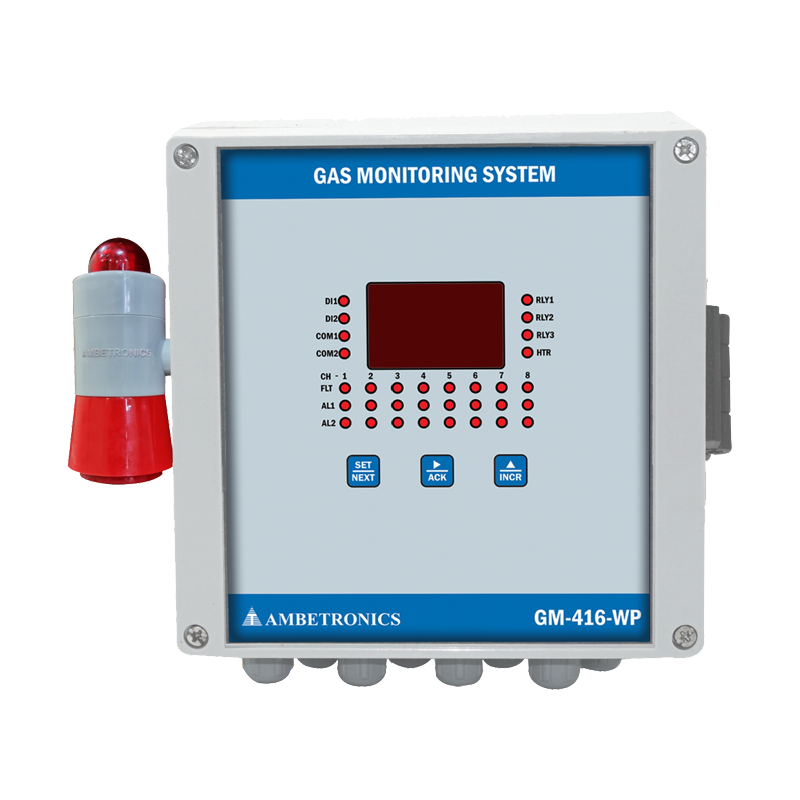

Gas Monitoring System GM-416-WP

- Flameproof certified for hazardous environments.

- Supports 8, 16, or 24 detectors.

- Integrated 2 x 4 digit LED Seven Segment Display.

- Features isolated RS-485 communication with Modbus RTU Protocol.

- The GM-416-FLP is a robust Gas Monitoring System designed for use in hazardous environments.

- It is flameproof certified to Ex-d IIC T6 Gb, IP66, ensuring safety in challenging conditions.

- This system can support 8, 16, or 24 detectors, making it versatile for various applications.

- Equipped with a 2 x 4 digit LED Seven Segment Display, it offers clear and easy-to-read information.

- Status indication includes DI-1 for Digital Input Signal-1, DI-2 for Digital Input Signal-2, and COM-1 for communication between master and slave devices.

- It also features COM-2 to indicate repeater communication between devices, PLCs, or SCADA systems.

- Relay indicators (RLY-1, RLY-2, RLY-3) provide information about the status of the relays.

- The system includes HTR-1 to indicate when the hooter is active.

- Control action involves three independent relays common for all channels that operate based on the slave status.

- Audible alerts are provided through the integrated buzzer and hooter in case of Alarm Set point violation.

- Range and resolution options include 0, 0.1, and 0.01.

- It supports an input of 8, 16, or 24 detectors via RS-485 MODBUS RTU port.

- The power supply requirement is 90 to 270 VAC, typically 230 VAC.

- For slave devices, less than 1.5 Amp at 24VDC is required for 8 channels. A junction box with SMPS is needed for 16 and 24 channels.

- The system supports a multidrop RS-485 port, eliminating the need for separate cabling to each detector.

- Password protection ensures security, and the system can be easily handled and programmed using three keys on the front panel.

| Bullet Yards and Storage Yards | Gas Cylinder Storage and Gas Refilling Stations |

| Building Management Services | Breweries and Steel Plants |

| Gas Turbines and Heat Treatment Plants | Leak Detection, Solvent Vapors |

| Personal Monitoring and Compressor Stations | Pulp & Paper Industry and Fuel Loading Facilities |

| Shopping Malls and Gas Stations | Gas Cylinder Bank Areas |

| Chemical and Hazardous Areas Requiring Data Monitoring | Gas Pipeline Projects and Burner/Furnace Areas |